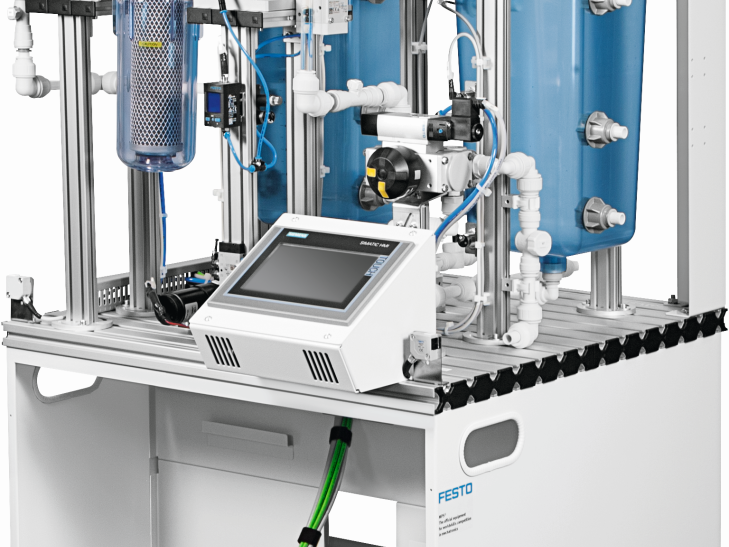

MPS PA filtration learning system

Filter, clean, rinse

The filtering station filters liquids. The filtrate is pumped from the first tank through the filter via a slide valve. The filtered liquid enters the second tank via the flap with pneumatic swivel drive. The filtered liquid can be pumped on to the next station using a separate pump. The filter can be backwashed with a rinsing program. To loosen deposits, the filter is also blown free with regulated compressed air.

Measuring, controlling and regulating

Sensors record the tank fill levels in the filter station. This allows simple control tasks for monitoring the pumps, through to complete control projects for complex process operations in the classroom.

The pressure control ensures consistently high filter quality during backwashing. The pressure sensor with LCD display, analog output and switching output always provides the correct measured variable. Via the proportional pressure control valve, the controller with P, PI or PID control algorithm ensures consistently high filter quality during backwashing. This provides clear and practical training in control technology.

Shut off, open, close

In complex process sequences, the correct selection of process valve, actuator, actuator accessories and control valve plays a decisive role. A wide variety of process components are used at the filter station. All valve actuators are controlled via a directly flange-mounted NAMUR valve.

Details

Learning objectives

- Construction, wiring and commissioning of a process plant

- Selection, use and control of process fittings

- Measuring electrical and process variables such as fill level and pressure

- Setting up and commissioning control loops

- Analysis of controlled systems and control loops

- Parameterization and optimization of P, PI or PID controllers

- Design of control and regulation programs

- Process operation and monitoring

- Inspection, maintenance and servicing