MPS PA Compact Workstation

The basics of control technology in the smallest of spaces

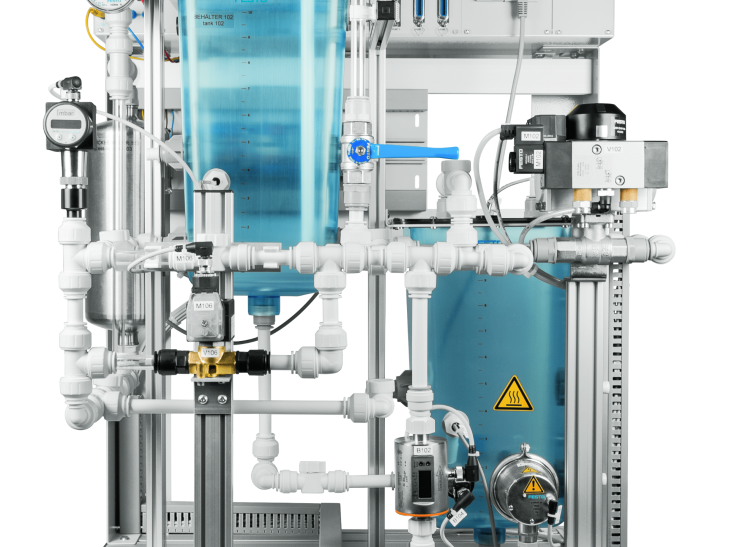

Function

The four controlled systems can be operated individually. The level and flow control system can be configured as cascade control with a corresponding controller (FluidLab-PA multi-loop required). The design of the sensors and actuators allows both continuous (e.g. P, I, PI, PID) and discontinuous controller types (e.g. 2-point controller). The pump can be directly controlled or speed-controlled

.

In the flow and pressure control sections, the control variable of the controller can also be used to control a proportional directional control valve. A 2-way ball valve with pneumatic rotary actuator is installed in the return flow between the elevated tank and the lower storage tank. This simulates a "consumer" in order to switch on a disturbance variable in the level control system.

The workstation has IO-Link components (level, temperature and magnetic flow sensors) for digital communication between devices.

Details

Learning objectives

- Introduction to process automation

- Learn the basics of control engineering.

- Read and design technical drawings for process engineering

- Get to know the different methods of control loop adjustment

- Operate, identify, configure and analyze various controlled systems for pressure, flow, level and temperature with industrial instrumentation

Design variants

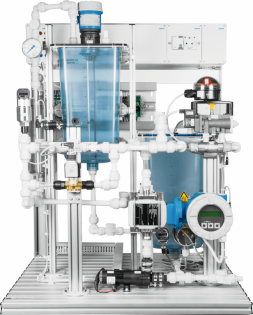

MPS PA Compact Workstation Basic

The MPS PA Compact Workstation Basic contains the mechanical and electrical components, sensors and drives that together form the process line.

MPS PA Compact Workstation Process Instrumentation

The MPS PA Compact Workstation Process Instrumentation is equipped with parameterizable sensors that can be used to familiarize yourself with the functions of typical control devices and the HART communication protocol down to the smallest detail.

MPS PA Compact Workstation Energy

The MPS PA Compact Workstation Energy is equipped with current and power meters to analyze energy consumption and efficiency.

Control versions

Without additional control

Each MPS PA Compact Workstation learning system contains the following control unit variant:

- EasyPort USB 19''

- FluidLab-PA closed loop (permanent license, 1 user)

Festo control unit/operating device

- CDPX 7'' touch panel operating device

- Integrated soft PLC Codesys V3.5

- I/O module 16 DI/DO, 4 AI/2 AO, directly on 2x SysLink/1x analog cable

- Software license Codesys V3 Runtime for CDPX

Siemens control unit/operating device

- EduTrainer Universal S7-1512C-1PN

- SIMATIC HMI MTP700 Unified Comfort with mounting frame

- STEP 7 TIA Portal programming software, single license

Rockwell control unit/ operating device

- EduTrainer Universal A4 Rack with Allen-Bradley 1769 L24

- 7-inch PanelView operating device