MPS Transfersystem

Move and combine

The MPS transfer system was developed for anyone who wants to make a difference in training. Be it for training in the electrical and metal trades or for mechatronics engineers, technicians and engineers.

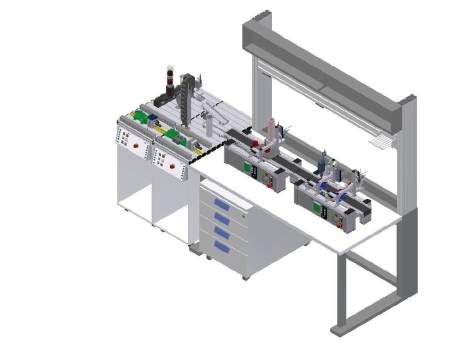

Innovative technology and the consistent use of industrial components characterize the main components of the MPS transfer system. The MPS transfer lines can be combined in a wide variety of ways and used flexibly.

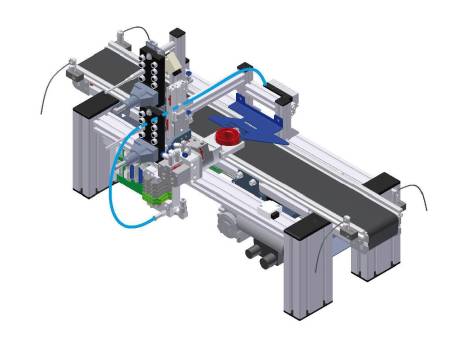

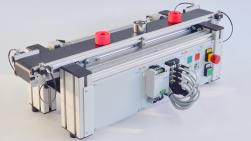

Design and function

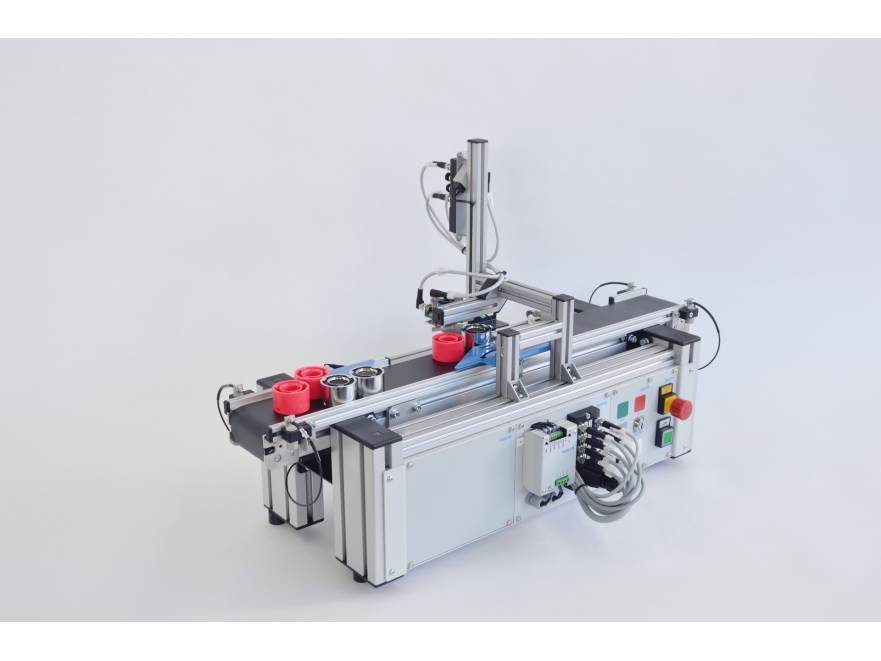

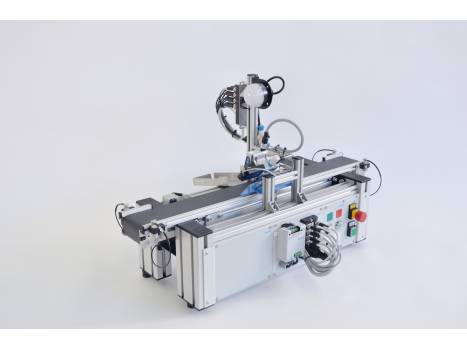

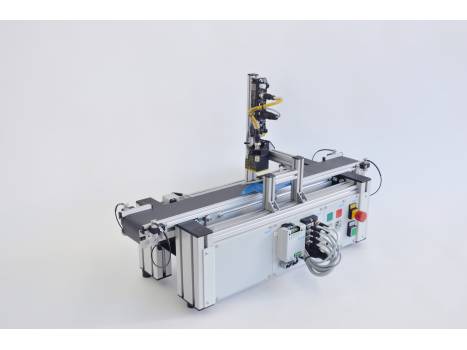

The transfer section is the basic element of the MPS transfer system. It consists of a belt, drive, operating elements and sensors and is fully assembled. Workpieces or workpiece carriers are transported here. The transfer line can be equipped with up to two mechatronic modules.

Modularly expandable

Easy to expand with different motors, controllers, inverters, operating units and connection technologies such as Profinet or I/O technology. Each line can be supplemented with a variety of modules. Even "standalone", many automation technology topics can be covered.

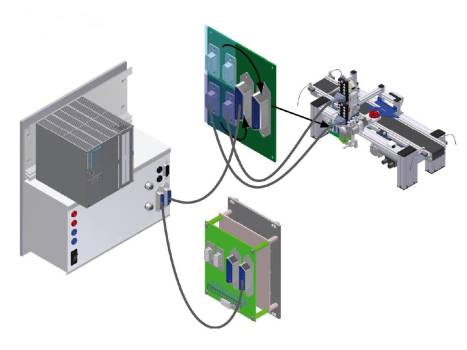

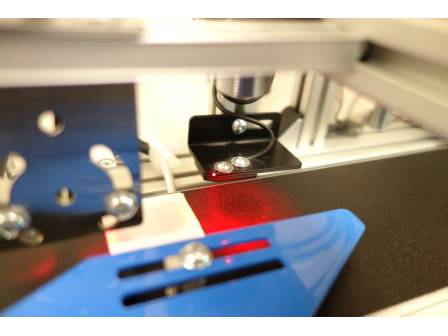

Intelligent connection technology

The system connections are designed so that all additional modules can be easily connected to the transfer line.

Product variety

An excerpt from the possibilities and topics that can be covered with the MPS transfer system.

Basic module

MPS transfer line MT DC

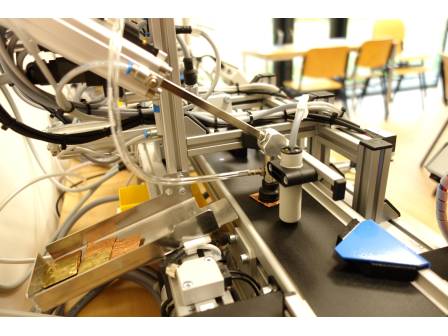

Modules, pneumatic

Module: Stacking magazine, pneumatic

Module: Turning, pneumatic

Module: Drilling, pneumatic

Module: Insertion, pneumatic

Module: Color detection/ pushing out, compressed air

Module: Measure analog/extend,

Vacuum

Modules, electrical

Module: Drilling, electric

Module: Vision system, electric

Module: RFID Siemens, electric

Module:RFID Turck,electrical

Module: Color detection/ejection, electric

Module: Measuring analog/offset, electrical

Module: RFID Siemens, electric

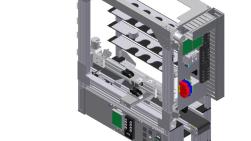

Module: High-bay warehouse

Further modules are available....

- Transfer line MT AC

- Borehole testing

- Pressing in

- ...

The modules are available in different versions

- I/O

- Profinet

- (Profibus)

Questions about the system

Get in touch with us to find out more.

Combinable

Flexibly expandable

special design - sorting of recyclable materials

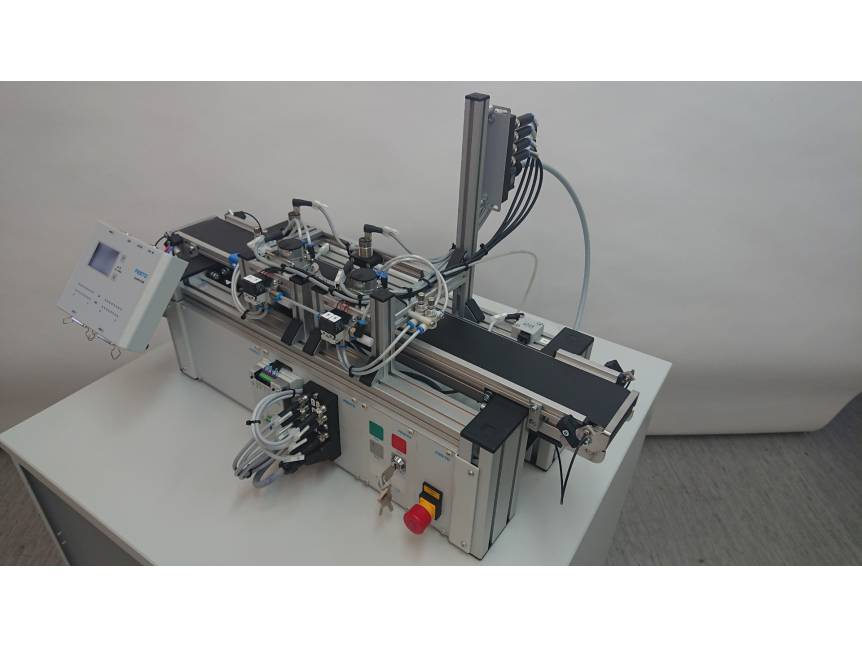

MPS TS Compact Trainer I4.0

The MPS transfer system forms the basis for the MPS TS Compact Trainer I4.0. Data is exchanged with the intelligent workpiece via an RFID read/write system that communicates with the controller using an IO-Link interface. The PLC has an integrated web server for fast process diagnostics using standard IT technologies. With the Raspberry Pi - the flexible gateway to the IoT - statuses can be archived, evaluated and displayed via the web server.